PIPELINE CRAWLERS BETATRON PORTABLE X-RAY DIGITAL RADIOGRAPHY

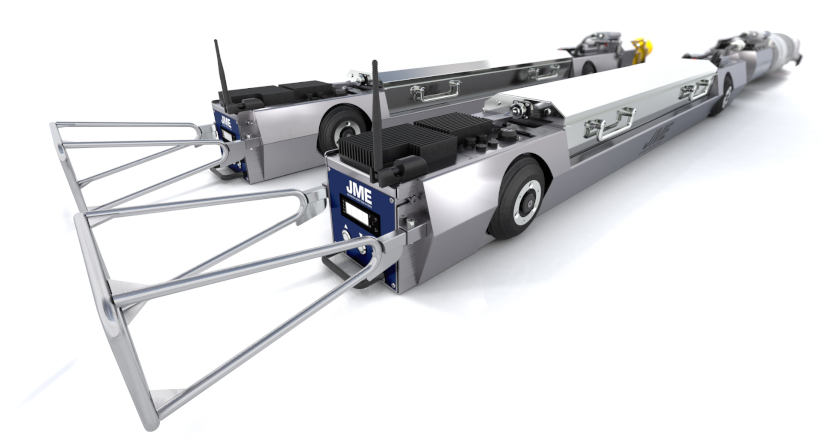

JME 10:CR2 Pipeline Crawlers are designed to produce high-quality panoramic radiographs of circumferential butt welds in new pipelines with an Internal Diameter (ID) between 9.5” to 48” (240mm to 1220mm). These units have been developed and proven to work as a fully self-contained, self-powered exposure vehicle both onshore and offshore. Compatible with X-Ray generators of various manufacturers including Balteau, Comet/Yxlon and ICM. The system also integrates with Gamma projectors made by SENTINELTM and Oserix. The JME Pipeline Crawler system is unique and the most versatile in the world.

JME’s unique Remote Handset allows external control and monitoring of the crawler whilst it is being operated within the pipe. The Handset is used to configure both the crawler and X-Ray generator prior to placing it into the pipe. JME’s 10:CR2 crawler also integrates both water and end of pipe sensors to provide protection against damage and give the owner/operator peace of mind.

NEW 10:CR2 FEATURES

| Simple adjustment from X-Ray generator to Gamma projector | Simplified and improved Wheel/Axle change |

|---|---|

| Remote Handset with multi language 4.3” TFT LCD touch-screen display | 60% increase in battery capacity allowing more exposures |

| Processor controlled allowing for software upgrade | Single magnetic Detector Box suitable for 0-40mm wall thickness Variable Crawler Speed |

| Customisable ‘Anti Run Away’ Integrated Radio Recovery AMAX Auto Move After X-Ray End Of Pipe/Water Sensor Kit | Variable Crawler Speed Control LED display on the rear of E-box for easier setup |

PROUDLY SUPPLYING THE NDT INDUSTRY FOR OVER 30 YEARS

10:CR2 NEW FEATURES

CR2 REMOTE HANDSET

MULTI LANGUAGE TOUCH SCREEN

JME’s unique Handset allows external control and monitoring of the crawler whilst operating in the pipe, providing real time data on the crawler’s activity. It allows the operator to enable/disable all features of the Crawler and X-Ray generator prior to operation, avoiding a lengthy, complex analogue configuration.

CUSTOMISABLE ‘ANTI RUNAWAY’

‘Anti Runaway’ is a system which puts the crawler into reverse if it does not receive a signal from the Magnetope or Handset within a specified time period.

INTEGRATED RADIO RECOVERY

In the event of a malfunction within the pipe, the crawler’s internal logic can be overridden by the handset to reverse the crawler out of the pipe.

AMAX – AUTO MOVE AFTER X-RAY

When AMAX is enabled, the crawler will locate under the Magnetope and be signalled to start the X-Ray. Once the exposure is complete the crawler will automatically drive to the next weld, increasing site efficiency.

END OF PIPE SENSOR KIT / WATER DETECTION SENSOR KIT

End of pipe and water detection sensors are fitted to the front and rear of the crawler. End of pipe sensors detect the Crawler’s proximity to the pipe entrance and stop the system automatically, preventing accidental damage to the equipment. Water detection sensors stop the crawler if water is detected within the pipe. A handset message is displayed in both instances to alert the user.

SIMPLIFIED AND IMPROVED WHEEL/AXLE CHANGE

The revised axle change system allows for easier set-up in the field.

SINGLE MAGNETIC DETECTOR BOX SUITABLE FOR 0-40MM WALL THICKNESS

A single Detector Box, covering the full spectrum of wall thicknesses up to 40mm. Removing the need to change the Detector Box as the wall thickness increases.

RANGE OF GAMMA PROJECTORS

Easy/simple crawler conversion from X-Ray generator to Gamma projector.

| Pipeline ID diameter range | 9.5” to 48” (240mm to 1220mm) |

|---|---|

| Weight (Excluding X-Ray Tube) | 265lbs (120Kg) |

| Length (Excluding X-Ray Tube) | 1717mm (246mm Recovery Ring) |

| X-Ray tube output options | 160kV – 360kV |

| Gamma projector options | SENTINELTM Delta 880 / Oserix Dual 120 |

| Power source | Sealed Lead Acid Batteries – 120V |

| Battery capacity | 24Ah |

| Average exposures per battery pack | 242 |

| Total travel distance per battery pack (Including exposures) |

3km |

| Motor rating | 1x 0.25HP (182W) |

| Travel speed | Up to 22 metres per minute |

| Maximum angle of climb (Optimum Conditions) |

20° / 36.4% |

| Mean positioning accuracy | ±5mm |

| Operating temperature range | -40oC to +70oC |