UT Blocks

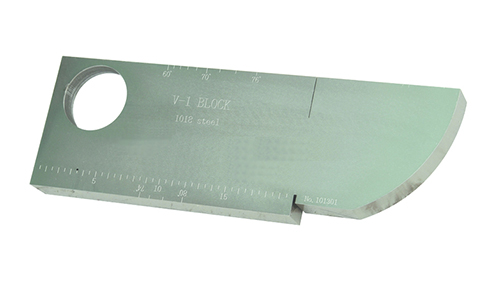

- The V-1 Calibration Block is used for calibrating ultrasonic flaw detection equipment in both laboratory and on-site conditions. It includes a 100mm radius, 1.5mm and 50.0mm holes, engraved reference mark scales, and slots at the zero point which provide calibrating signals at intervals of 100mm range. In accordance with British standard BS 2704 Block A2 Mod. 1, DIN 54-120, and ISO 2400.

• Dimensions: 300mm*100mm*25mm

• Engineering plastics storage cases

• Net weight: 5.0kg

• Gross weight: about 6.5kg 2. The V-2 Calibration Block is a small calibration block for on-site checking of miniature shear wave probe index, time base, beam angle and gain. It includes a 25mm and 50 mm radius, 5mm hole(or 1.5mm), engraved reference mark scales from 35 to 75 degrees. In accordance with British Standard BS 2704 block A4, DIN54122.

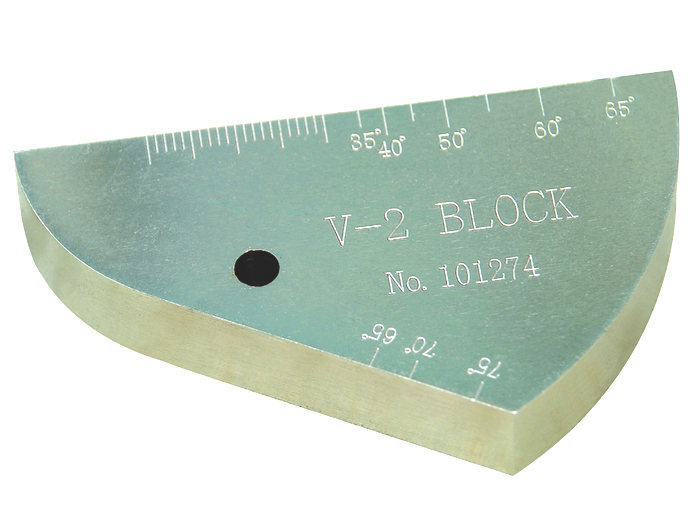

2. The V-2 Calibration Block is a small calibration block for on-site checking of miniature shear wave probe index, time base, beam angle and gain. It includes a 25mm and 50 mm radius, 5mm hole(or 1.5mm), engraved reference mark scales from 35 to 75 degrees. In accordance with British Standard BS 2704 block A4, DIN54122.

• Dimensions: 75mm*43mm*12.5mm

• Engineering plastics storage cases

• Net weight: 0.5kg

• Gross weight: about 0.75kg 3. The DC Calibration Block is used for shear wave distance calibration. It contains a 25.4mm radius overlaying a 50.8mm radius on a 180°segment. In accordance with ASTM E164 and BRR/AWS X-1 specifications.

3. The DC Calibration Block is used for shear wave distance calibration. It contains a 25.4mm radius overlaying a 50.8mm radius on a 180°segment. In accordance with ASTM E164 and BRR/AWS X-1 specifications.

• Dimensions: 50.8mm and 25.4mm radii

• Engineering plastics storage cases

• Net weight: 0.5kg

• Gross weight: about 1.5kg 4. The SC Calibration Block is AWS-type block which used for shear wave sensitivity calibration. It includes two .062″ diameter through holes(1.6mm holes). In accordance with ASTM E164 and BRR/AWS standards.

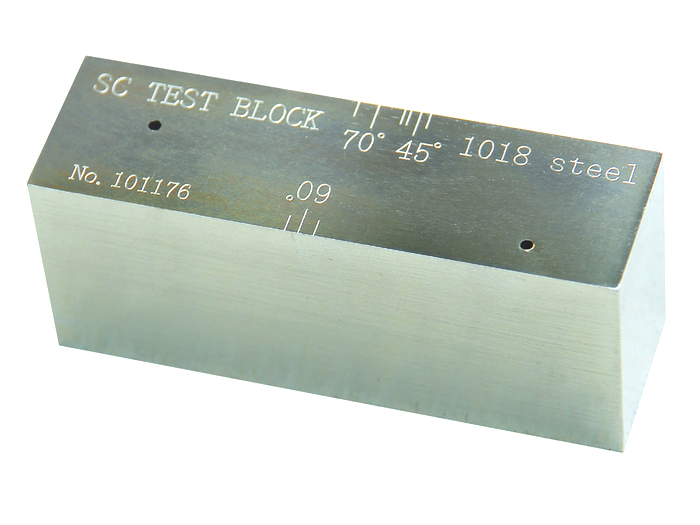

4. The SC Calibration Block is AWS-type block which used for shear wave sensitivity calibration. It includes two .062″ diameter through holes(1.6mm holes). In accordance with ASTM E164 and BRR/AWS standards.

• Dimensions: 76.2mm*31.75mm*22.99mm

• Engineering plastics storage cases

• Net weight: 0.5kg

• Gross weight: about 1.0kg 5. The DSC Calibration Block is a AWS-type Calibration Block which used for shear wave distance and sensitivity calibration, it contains a 25.4mm radius overlaying a 76.2mm radius, in accordance with ASTM E164

5. The DSC Calibration Block is a AWS-type Calibration Block which used for shear wave distance and sensitivity calibration, it contains a 25.4mm radius overlaying a 76.2mm radius, in accordance with ASTM E164

• Dimensions: 25.4mm and 76.2mm radii

• Engineering plastics storage cases

• Net weight: 0.75kg

• Gross weight: about 1.25kg 6. The 4-Step Calibration Block is for thickness and linearity calibration. This 4-Step block comes in thicknesses of 6.25mm, 12.50mm , 18.75mm , and 25.00mm . Step face measures 20.00mm * 20.00mm . In accordance with ASTM E797.

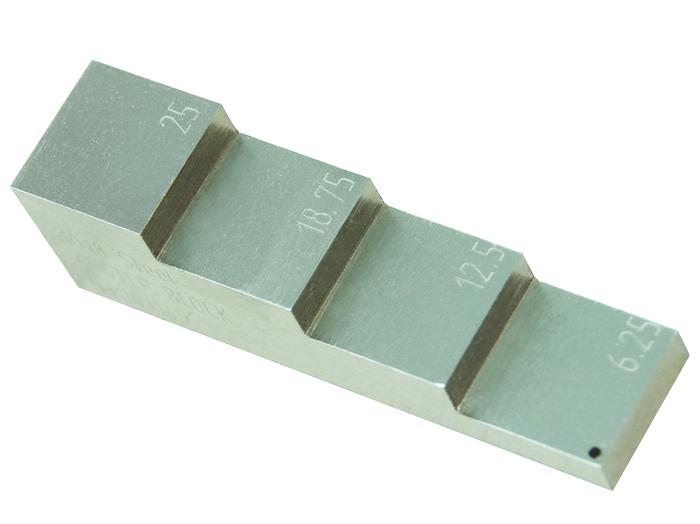

6. The 4-Step Calibration Block is for thickness and linearity calibration. This 4-Step block comes in thicknesses of 6.25mm, 12.50mm , 18.75mm , and 25.00mm . Step face measures 20.00mm * 20.00mm . In accordance with ASTM E797.

• Dimensions:80mm*20mm*25mm

• Engineering plastics storage cases

• Net weight: 0.2kg

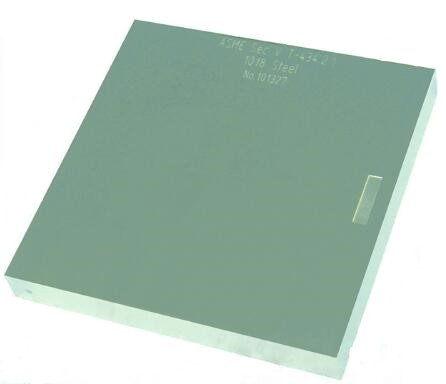

• Gross weight: about 0.6kg 7. ASME Basic Calibration Block 1 is used for establishment of primary reference responses for UT examination of welds. ASME Basic Calibration Block 1 contains three side-drilled holes at 38mm deep minimum at 2.5mm diameter. The hole locations through the thickness are 1/4, 1/2 and 3/4 T. it also contains 2 EDM notches measuring 2% T deep * 6.4mm max wide * 25 long min. In accordance with ASME Sec V T-434.2.1

7. ASME Basic Calibration Block 1 is used for establishment of primary reference responses for UT examination of welds. ASME Basic Calibration Block 1 contains three side-drilled holes at 38mm deep minimum at 2.5mm diameter. The hole locations through the thickness are 1/4, 1/2 and 3/4 T. it also contains 2 EDM notches measuring 2% T deep * 6.4mm max wide * 25 long min. In accordance with ASME Sec V T-434.2.1

| Weld Thickness (mm) |

Block Dimension(mm) Thick*Wide*Long |

Net Weight |

Gross Weight |

Packing |

| Up to 25 | 19*150*150 | 3.5 | 4.5 | Engineering plastic cases |

| Over 25 through 50 |

38*150*200 | 9 | 10 | |

| Over 50 through 100 |

75*150*250 | 23 | 24 | |

| Over 100 | 125*150*381 | 58 | 62 |

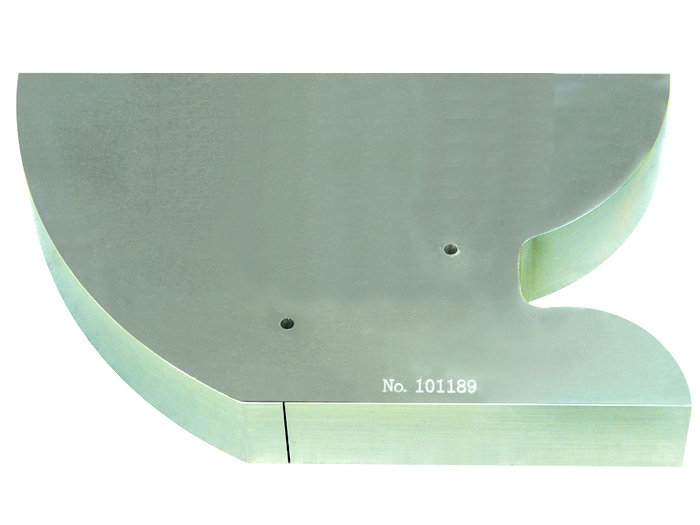

• Dimensions:150mm*90mm*25mm

• Engineering plastics storage cases

• Net weight: 2.0kg

• Gross weight: about 3.0kg

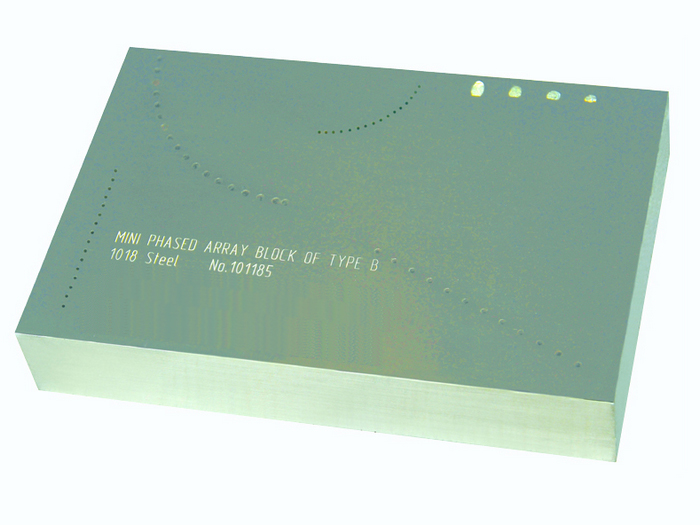

(The Mini Phased Array Calibration Block B contains eighteen 2.0mm diameter through-holes for 50mm radius and eighteen 1.0mm diameter through-holes for 25mm radius, sixteen 1.0mm diameter through-hole for 90°, twelve 1.5mm diameter through-holes, four angle through-hole.)

• Dimensions:150mm*100mm*25mm

• Engineering plastics storage cases

• Net weight: 3.0kg

• Gross weight: about 4.0kg

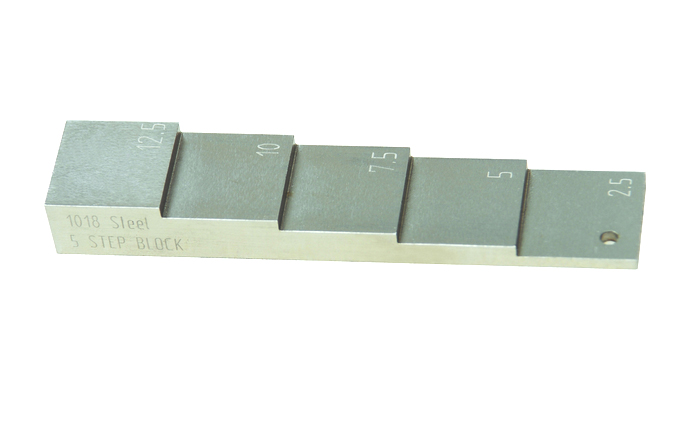

10. The 5-Step Calibration Block is for thickness and linearity calibration. This 5-Step block comes in thicknesses of 2.50mm , 5.00mm , 7.50mm , 10.00mm and 12.50mm. Step face measures 20.00mm * 20.00mm. In accordance with ASTM E797.

• Dimensions:100mm*20mm*12.5mm

• Engineering plastics storage cases

• Net weight: 0.25kg

• Gross weight: about 0.63kg

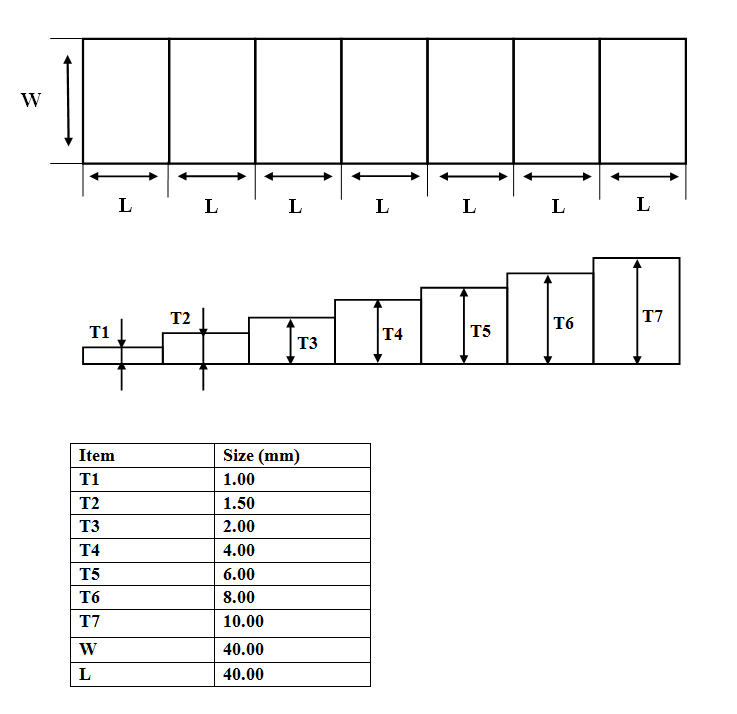

11. 10-Step Calibration Block is a Special step block for thickness and linearity calibration. It goes from 1.0mm to10.0mm in 1.0mm increments. Face measures 20mm*20mm.

• Dimensions:200mm*20mm*20mm

• Engineering plastics storage cases

• Net weight: 0.2kg

• Gross weight: about 1.1kg

12. The IIW-Type 1 Calibration Block is used for calibration of shear and longitudinal transducers, and verification of shear wedge exit point and refracted angle. Can also be used for resolution and sensitivity checking, in accordance with international institute of welding and ASTM E164 specifications.

• Dimensions:300mm*100mm*25mm

• Engineering plastics storage cases

• Net weight: 5.0kg

• Gross weight: about 6.5kg

13. The IIW-Type 2 Calibration Block is a modified version of the original IIW-Type 1 Calibration Block. It includes a 50 mm radius x 6 mm deep cut-out superposed on the 100mm radius for distance calibration. Also includes numbers 1 mm, 2 mm and 3 mm through holes and distance calibration marks to the 50mm hole. In accordance with International Institute of Welding and ASTM E164 .

• Dimensions:300mm*100mm*25mm

• Engineering plastics storage cases

• Net weight: 4.5kg

• Gross weight: about 6.5kg

14.The Japanese Industrial Standard-STB-G Calibration Block are a series of test blocks containing flat-bottom holes and are used in straight beam (normal) testing. They are used to adjust the working sensitivity, to measure the characteristics of the normal beam probe, and to measure the overall performance characteristics of the ultrasonic test equipment. All versions are offered, including the STB-G V2, V3, V5, V8, and six V15 blocks. Each block contains a unique metal-travel distance, flat-bottom hole diameter, and overall block size.

15. The 7 step Calibration Block