It is suitable for fast and high-precision automatic inspection of alloy steel short bars. The system can realize automatic loading and unloading, and according to the intelligent ultrasonic evaluation technology, realize the automatic sorting of bars, which greatly improves the detection efficiency and reduces misjudgment.

Performance Indicators

Technical Specifications

- Scope of application: customized

- Probe specifications: 2.5-15 MHz, 64-256 concave phased array probes can be customized according to bar diameter and detection standards

- System repeated positioning accuracy: ± 0.05mm

- Detection efficiency: Under the requirements of high-precision testing, 1m bars can complete testing within 3min

- Detection accuracy: AAA

System Composition

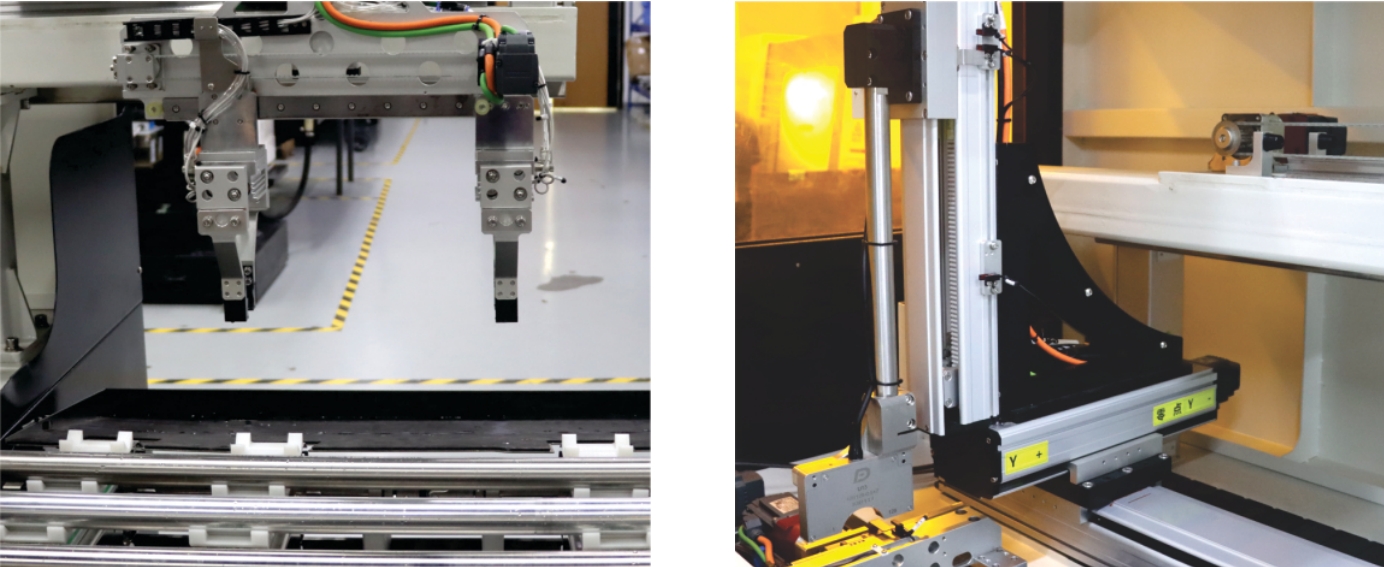

The bar phased array ultrasonic water immersion detection system is composed of inlet and outgoing conveying line, workpiece handling manipulator, workpiece rotating clamping mechanism, XYZ three-axis detection module, probe holding tooling, detection sink, equipment support, NG product discharge tank, electrical control cabinet, touch screen, etc.

Detection Process

With fixed sink testing, the bar rotates at a specified angle, and the concave array probe performs the inspection in a straight reciprocating manner. Internal defects of the bar can be detected through multiple sets of different focusing rules. The detection results are displayed as visual C-scan.

Technical Advantages

- With intelligent defect identification and extraction technology, it can obtain excessive defect information according to standards, and automatically generate defect statistical tables, which greatly reduced the workload of evaluation.

- The system operation is stable and reliable. Using phased array technology, it greatly improves the detection efficiency; also reduces the mechanical rotation time and improves the detection stability.

- Optional real-time 3D display function to better view the location of defects. This system adopts a ROBUST phased array card, with a data transmission rate of up to 90M/s, and automated data transmission is pressure free. At the same time, portable products can be selected for manual re-inspection.

- It can achieve automatic loading and unloading of workpieces, automatic gripping of workpieces by the handling robot to the detection station, automatic gripping of workpieces by the rotating clamping mechanism of the XYZ three-axis module, driving the ultrasonic phased array probe to detect the workpieces. After the detection is completed, workpieces can be automatically sorted, greatly reducing workload