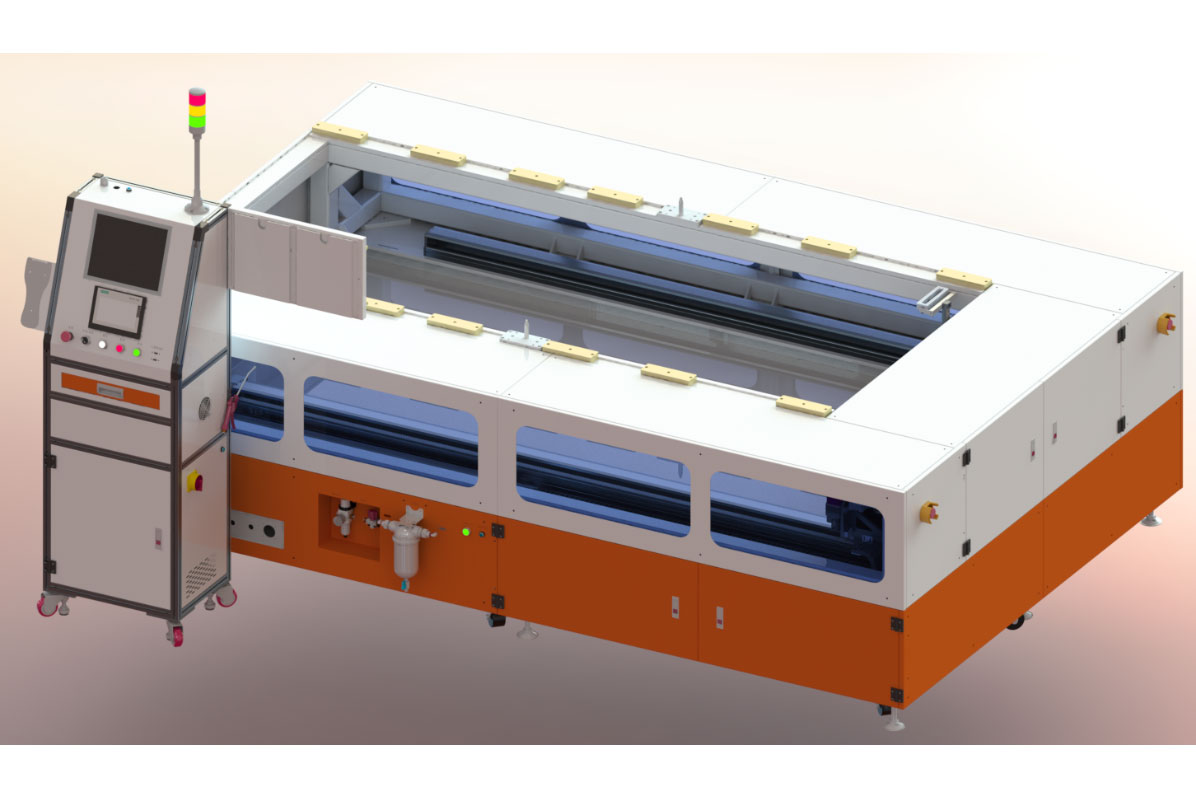

The phased array ultrasonic testing system is suitable for high-precision testing of the gluing quality of various types of workpieces. The system includes ROBUST phased array board, automatic multi-axis scanning system, and is equipped with high-frequency, large array element probe which is specially designed. It can quickly realize the large area & two-dimensional scanning, with clear imaging and excellent effect, and realizes the high-speed visual testing of the gluing quality. The intelligent analysis system can automatically generate the adhesive rate analysis after scanning , which can save time and help complete data analysis.

Performance Indicators

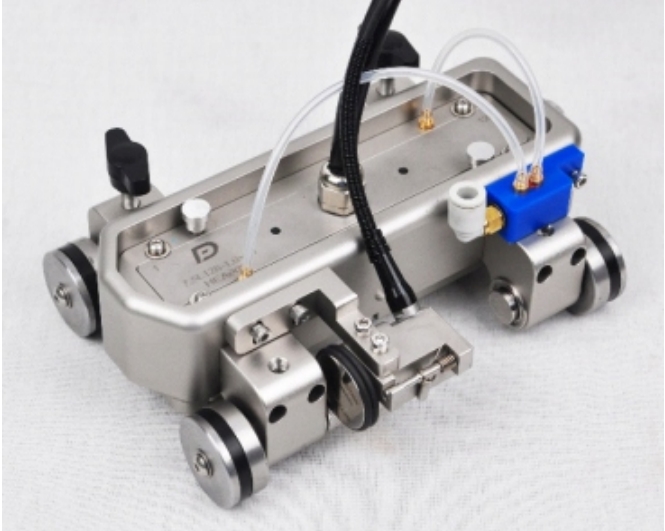

Probes and Fixtures

- The probe adopts the design form of large array element probe.

- The single effective beam coverage width can reach 120mm, which greatly improves the detection efficiency.

- With spring pressure mechanism to ensure good coupling between the ultrasonic probe and the workpiece.

Automated Analysis

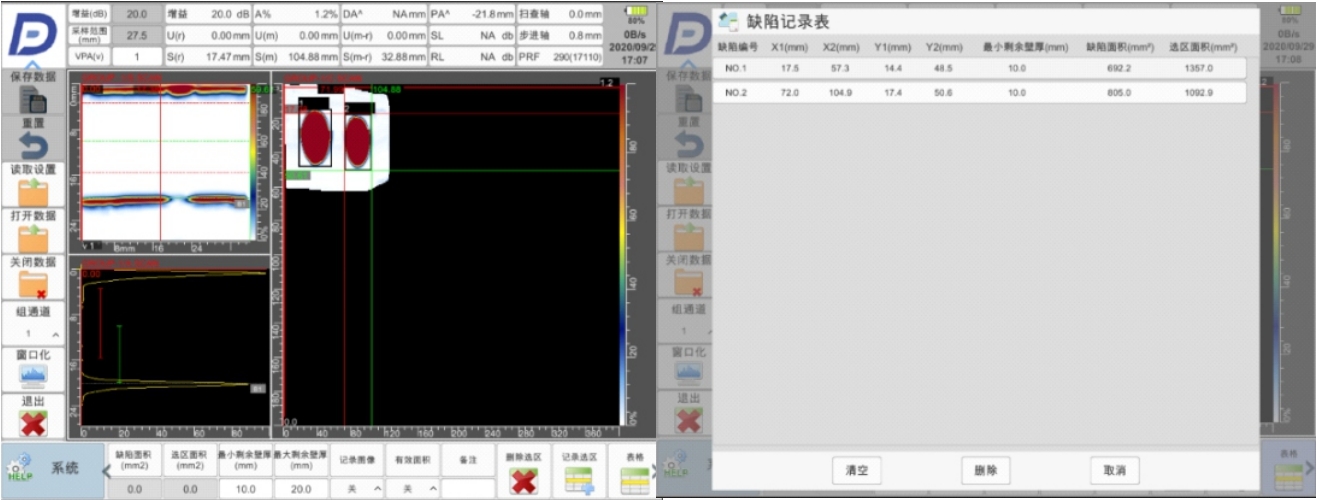

Due to the large detection area, a two-dimensional scanning is required, and as the scanning process progresses, the two-dimensional C-scan imaging area will be filled synchronously. After the detection is completed, the software automatically analyzes the current detection data , selects the missing or poorly bonded areas contained in the current data in the two-dimensional C-scan image according to the gate setting. The area of the missing or poorly bonded areas is calculated, and the effective area of gluing is obtained according to the total detection area.

Visual Detection

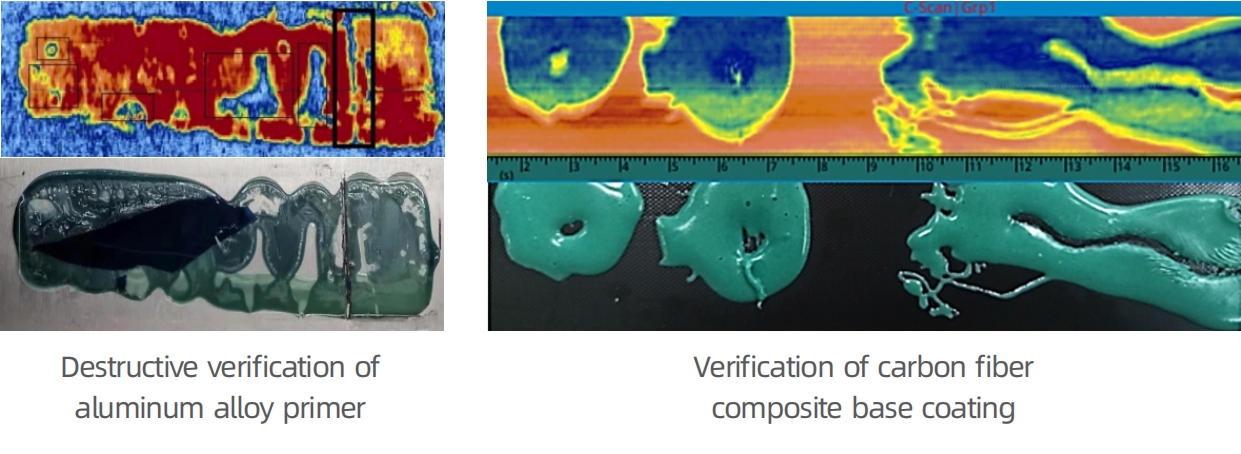

The experiments on the bonded samples to be tested were carried out, and the comparison with the later anatomical diagram is as follows, which shows that the phased array ultrasonic detection image is basically the same as the gluing shape of the destructive dissection, which strongly verifies the feasibility of phased array ultrasonic non-destructive testing technology in bonding quality detection.

Smart Judging

After the test is completed, the system determines whether the current test object is qualified according to the qualified effective gluing area, and displays OK or NG. When it is unqualified the system will alarm.