SINGLE WALL SINGLE IMAGE (SWSI) + DOUBLE WALL SINGLE IMAGE (DWSI) OPERATION

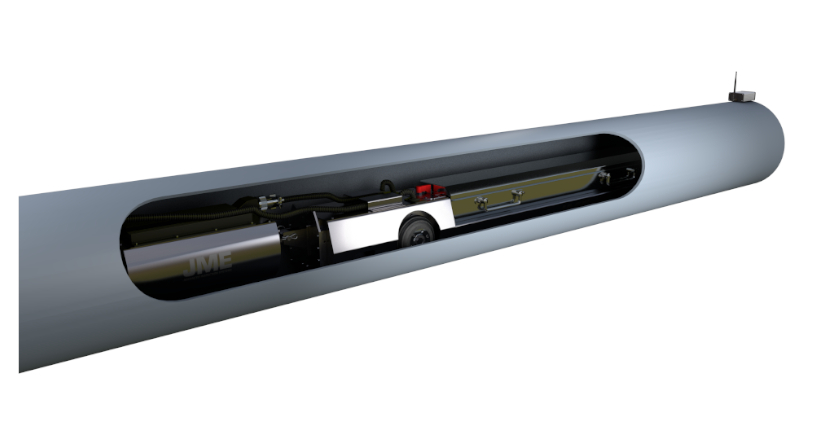

JME would like to present our newest product, the DXB:1 Digital X-Ray Buggy; designed to produce high-quality panoramic digital radiographs of circumferential welds in applications such as new pipelines. As a versatile and configurable system, it can also be utilized for use in various non-pipeline applications, such as the inspection of tank walls or other ferrous metal structures.

This digital system is a replacement for traditional film radiography; so no more chemical processing, dark rooms, or flaws associated with conventional radiography. The DXB includes a high-definition digital panel for instant verification of image quality and system settings. Images are digitally stored, preventing the need for film storage and enabling a permanent record to be saved within the control tablet. These can be backed up via USB or using a Network connection, allowing the images to be sent to an off-site Radiographer seconds from acquisition.

JME’s DXB system also communicates and integrates with our entire CR2 Pipeline Crawler Range. This allows 2-way communication between the Pipeline Crawler and DXB, giving configuration of key crawler parameters from the DXB control tablet. This integration also allows commencement of inspection with the push of a single button. The DXB operator is able to control, adjust and view the status of the CR2 crawler at all times during an inspection task.

With a rapid magnetic deployment system, the DXB:1 can be positioned by a single person in less than a minute. The system is attached using permanent magnets, meaning in the event of a loss of power the unit will remain firmly attached to the pipe. This quick and efficient deployment dramatically increases productivity on-site. There is no need for welding bands to be deployed and relocated between each inspection which again greatly improves efficiency on-site.

- Deployed in seconds, no welding bands required

- Film replacement technology

- Allows for ‘Cloud-based’ image inspection

- Fully integrated with crawler operation

- Integrated functionality with the CR2 Remote Handset Unit

- One-touch inspection

- Comprehensive safety interlocks

- Automatic back-up of images

- Digital storage of images locally or web-based

- Magnetic mounting

| Buggy Width | 220mm |

|---|---|

| Pipeline Diameter | 10” (254mm) |

| Average Scan Speed | Minimum: 15 mm/s |

| Typical | 22 mm/s (including imaging time and movement between images) Depending upon pipe schedule |

| Image Quality | Image quality class B acc. ISO19232-5, ISO 10893-7, ISO 17636-2 |

| Image Format | DICONDE compliant data export, via Ethernet or USB |

| System Weight | Buggy, Detector and Battery – < 44.1 lbs (< 20Kg) |

| Dimensions (mm) | Overall Package Kit – 687(L) x 528(W) x 552(H) |

| Positioning | Manually positioned directly onto pipe cut-back with no bands |

| Operating Temperature | -20°C to +60°C |

| Power Consumption | <50W |

| Imaging X-Ray Energy | Up to 300kV |

| Image Storage Capacity | 500+ Images @ 36” pipe |

| IMAGING | |

| Resolution | 100 µm |

| Technology | CMOS |

| Image area | Width: 100mm Length: up to 150mm per image (depending upon pipe diameter) |

| Image Stitching | Uses image feature matching algorithm |

| CONTROL TABLET SPECIFICATIONS | |

| Display | 10.1” 10-point capacitive multi touch screen, high definition, daylight readable, Waterproof digitizer pen for improved ease of use |

| Certification | MIL-STD-810G certified IP65 certified sealed all-weather design |

| Power Option | Li-ion 11.1 V, 4200 mAh |

| Dimensions (mm) | 269(L) x 188(W) x 20(H) |

| Weight | 2.4 lbs (1.09Kg) |

| Operating System | Windows© 10 Pro |

| BUGGY POWER OPTIONS | |

| Battery Specifications | 54V 2000mAh |

| (DeWalt Flexvolt) | 54V 3000mAh 54V 4000mAh = 125 shots* (18” Pipe) *Average shots – dependent upon system settings |

| CONTROL SYSTEM | |

| User Interface | Touch-screen display, with intuitive controls. Image viewing and assessment functions for on-site checking of acquired images prior to formal interpretation. |

| Image Acquisition | Automatic acquisition process, controlled by user. |

| Crawler Control | Full crawler control integration, to synchronise crawler operations and image acquisition. |

| DXB:1 PACKAGE CONTENTS | |

| DXB BUGGY | |

| 2X SPARE BATTERIES | |

| BATTERY CHARGER | |

| TOUGH PAD | |

| 2X TOUGHPAD SPARE BATTERIES | |

| TOUGH PAD CHARGER | |

| RAID-1 CONFIGURED EXTERNAL USB HDD | |

| ASSORTMENT OF ARIELS, ADAPTERS AND IQI’S | |

| BOX OF CHARGING and DATA LEADS | |

| 3 MONTHS TRIAL DURR SOFTWARE | |