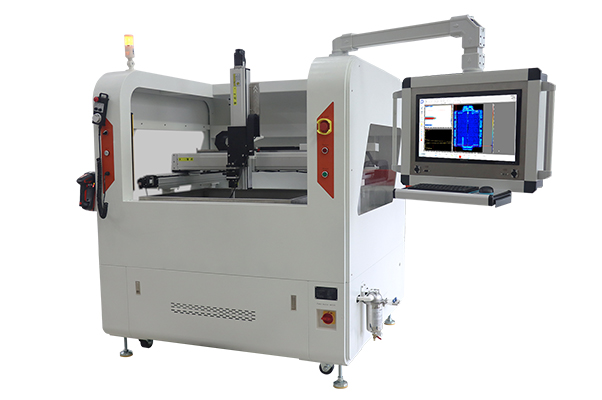

The automatic ultrasonic immersion inspection system is suitable for high-precision imaging detection of the welding quality of water-cooled plates. The system adopts a special customized processwith a detection accuracy of up to ф 0.2mm flat bottom hole equivalent and is the best solution to meet high-end water immersion testing needs. This system is compatible with various specifications of water-cooled plates and can also be extended to water immersion testing of automotive components, aerospace components, and other precision components.

Performance

Detection Mode

With the use of high-precision automatic X, Y, Z three-axis module, it can realize automatic X-Y twodimensional grid scanning or manual detection, and the scanning axis and step axis can be customized. Auto or manual mode can be automatically switched. Automatic A/B axis and manual A1/B1 adjustment axis for fine-tuning probe angle are provided for optimal inspection results.

Technical Parameters

- XYZ (customizable): 800x600x400mm

- Repeatable positioning accuracy: less than 0.05mm/m

- System position resolution: <0.01mm

- Scanning speed range: 1mm/s ~ 500mm/s

- Equipment working temperature range: -10°C ~ +40°C

Motion Control Software

The motion control software can help realize manual control of each axis and automatic detection of grid. The source code for secondary development can be provided to users, users can promote secondary development refers to the motion control design manual, which is compatible with VC, VB, VS, C++Builder, C# and other development software.

System Composition

The system is composed of ultrasonic board, industrial computers, displays, multi-axis motion modules, detection sinks, probe clamping tooling, equipment brackets, control cabinets, water circulation filtration systems, etc.

Technical Advantages

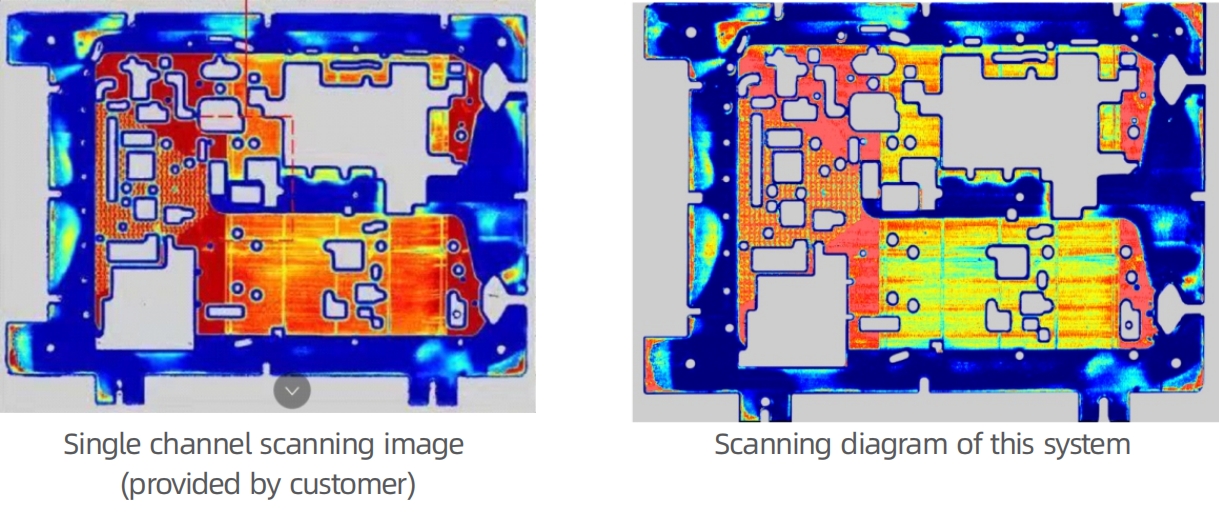

- Clear imaging: high-frequency special customized probes are used to achieve high-precision imaging of water-cooled plates.

- Automatic defect evaluation and workpiece statistics: According to the detection standards given by customers, it can automatically identify defects and count the number of defective workpieces, and easily realize workpiece statistics.

- Strong process applicability: one detection process can be applied to a variety of water-cooled plate testing, reducing equipment debugging time and improving detection efficiency.

- Stable operation: the whole system is stable in operation, safe and reliable, convenient for maintenance, especially suitable for small batch, multi-variety workpiece detection.

Typical Detection Map