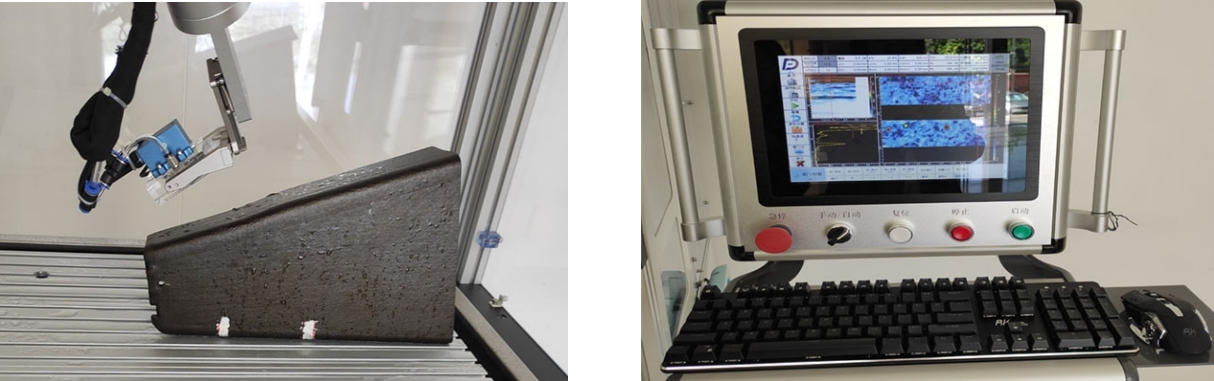

The system is composed of UR3 six axis manipulator, equipment rack, workpiece installation and testing platform, ultrasonic board, industrial computer, display and water supply system, which can be used for rapid and automatic detection of composite materials. Six axis mechanical equipment has flexible movement and high position accuracy; With the help of ultrasonic card, the defect can be identified automatically. The system can also be extended to auto parts batch rapid detection (small workpiece), with a wide range of application prospects..

Performance Indicators

Technical Advantages

- It can be used for the rapid and automatic detection of composite materials.

- The six-axis mechanical arm has flexible movement and high displacement accuracy.

- With the Robust PAUT Board, it can realize automatic defect identification.

- The system can also be extended to rapid detection of automotive components (small workpiece), with a wide range of application prospects.

- Suitable for automatic ultrasonic inspection of special-shaped workpieces.

System Composition

The system is composed of six-axis mechanical arm, equipment rack, workpiece installation and testing platform, industrial computer, display and water supply system, ultrasonic board, ultrasonic phased array probe and wedge, etc. Automatic ultrasonic detection, simple instruction and easy operation .

System Parameters

- Size of workpiece installation and testing platform 600mm x 600mm.

- The operating voltage of the six-axis mechanical arm is DC48V, with no interference to the ultrasonic signal, and the working radius is 0.5m.

- Six axis robotic arm teaching manual dragging, easy to operate, and can quickly complete the scanning trajectory planning of the workpiece.

- Manual and automatic scanning options are available.

- Equipment power supply AC 220V.

- Size: length*width * height:1m * 1m * 2m.